After seeing Febi's head, I would have a head done by the same guys. It will flow as well or better than a modded m44 head. With these guys, there is no need for solid lifters as they left the hydraulics in. You just have to figure out the right combo for it to work.

The bad side is that while you will have a head ready for 8k, your bottom end will not be. Jim did a bit of specialty work on the bottom end with oil flow and bearings, as well as putting in a windage tray. He does not want some of the oiling tricks revealed as they are key to making 8k reliably, you can do it with normal parts, but not reliably. Work is done to the block, bearings, pistons and rods to ensure things will last.

Head...

The Head was polished/ported, flow benched, and every moving part's weight was reduced. I am not sure if the chamber size was changed or if the valve sizes are stock though. The buckets were swapped for lighter (less oil capacity), and the valve stems and springs are shorter (stems are also thinner) for less weight to carry. Keep in mind, with the 4 valves, there is not much room to increase size as they will begin to shroud each other. Brass guides were put in place on all valves, the seats were recessed and use a brass insert as well. Retainers are ti, and the springs are special rate beehive shape. I know Jim spent a lot of time on spring rate vs. the lifter, so I will not go into the actual rate he uses. Also at these speeds, oil weight will make a difference in how the system works as 8k on hydraulic lifters is a tricky thing to do. While the buckets, retainers, and valves are easy to source, the springs are not off the shelf parts.

Intake...

My understanding is that the intake is not holding the engine back, in fact it apparently flows decent already. It is the AFM that will hold you back if anything.

hi, thanks for the reply! i'm not running an AFM, I'm running megasquirt, so that potential restriction is gone. fwiw when I had the 1.8 on the rollers I hooked up a perssure gauge to the intake to see if it was a restriction, as on the S14 there is some due to the AFM on WOT, but there isn't on a standard M42. not to say there wouldn't be now i have a much bigger capacity. i'd have although thought our intake manifold + throttle body may be problematic, but I'm going to be running my ITBs anyway.

as for febi's, its running m50 lifters, isnt it? the valve size is standard, and the valve stem dia is just the late m42 dia. febi said that little was done in terms of flowing to his head. as for the lower mass of the valvegear, that's the case with the later m42 valvegear, not just febi's car.

as far as using those guys is concerned, that's not really an option being in the UK - I'd get stung at customs and for postage on something so heavy, plus it's quite likely to get damaged in transit. it's also against the ethos of the project, i built the bottom end so I see little reason not to build the head. i know they did some great work on febi's car, but being a walking advert for them is not helpful for me as I can't pop down and have a chat with them being several thousand miles and an ocean away! i may email them and ask them for a quote and for the rate of their valve springs, and their guides etc though. i will also pop dbilas an email and ask them about their choice of rates with valve springs. given that they build group N and other highly modified m42s I expect they will be more upfront with their information.

I'm not sure what you are suggesting in your post when you say that febi's will flow as well if not better than an M44. are you suggesting that a standard M44 head flows better than the standard M42 (as well as being quieter and having less friction!)?

if you look at the S42, euro S50b30, euro S50b32, S54 you'll see that they run the same bore spacing and similar piston size to me yet run bigger inlet valves. if you compare our inlet valve size to other 4 potters that make good power per litre, ones with similar piston dia too, our inlet valves are def on the small side. i agree about shrouding, and this is one of the reasons i'd like to see the underside of a euro s50 head with its bigger inlets. but if you look at the head on a car such as the s2000, whose head is supposed to be about as good as it gets, the inlet valves are closer together than on the M42 (fwiw they're also much bigger than an m42!). there is room for slightly larger inlet valves imo without too much shrouding.

as inlet valve area is so critical to power output, leaving the standard inlets in is not really an option to me, and having used so many euro S50 parts in my engine build, it makes sense to me to run inlet valves of the same diameter, or at least close to that diameter. otherwise that's just one more disadvantage we have against the 95bhp/litre euro s50b30 (others include solid lifters, infinitely variable vanos on the intake cam, longer stroke) not to mention the s50b32 and s54 which have even bigger inlet valves.

just consider cars that make really good bhp/litre and have near identical piston size to me - for a start peugeout mi16 head and s2000 both have bigger inlets not only than our heads but than an S50, yet the same piston size. imo leaving the standard inlet valves in is capping the power output, i want to run 75 odd bhp extra power over standard, and leaving the standard inlet valve size with such an increase in power sounds nonsensical. the midrange and part throttle power will also be improved with larger inlet valves.

i may well get my spare m42 head on a flowbench and see just how good it is at various lifts. I also have a friend who works for cosworth, so i may donate this head to him for messing with if i can get him interested! it does seem like a bit of a pointless exercise, you can see its limitations without a flowbench i think. an s50 head for comparison would be really helpful, i may see if i can buy a wrecked one.

as for the bottom end, that's not very helpful! fwiw i know my rods, pistons and crank will take the rpm i'm looking at, i'm more interested in these other mystical changes. i'm not sure that i'm up for altering the oilways unless i see good reason to do so, but if any changes have been made to the pump i'd like to hear about it.

i'm ultimately trying to get the best inlet port design and biggest inlet valves i can squeeze into the m42. if you look at m42 inlet ports, the radius seems much greater than heads such as an s2000 head or an s14 head etc, and the diameter likewise is very small indeed. the approx diameter of an m42 inlet port is 23mm, compared to 26mm for a standard s14 and up to 28mm on the evo2. the entry is also much smaller and the radius is very big. the length however is very similar to the s14. it looks like the m42 port needs a load of work to flow as well as i'd like. here's some pics:

M42

S14

notice how if you follow a straight line from the entry of the port you hit the top of the valve and the valve stem seal on the m42, if you do the same on the S14 you hit the back of the middle of the valve. the s14 port is also a fair bit bigger. i think the m42 has potential though as the angle of entry of the S14 port is pretty steep. if i could get the m42 to have a bigger dia and less of a radius while having a slightly less steep entry angle, i think it would have potential.

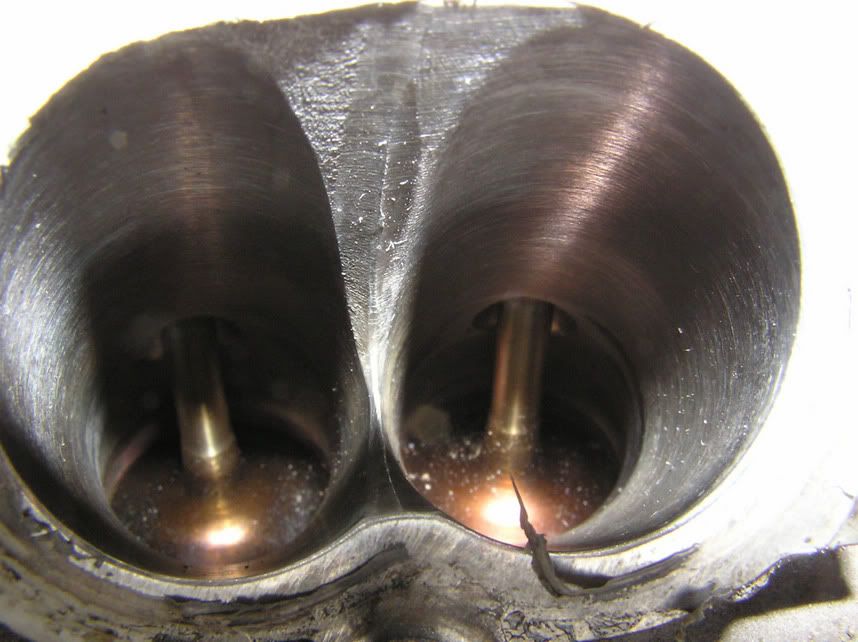

here's the underside of my spare, manky head:

apologies for the state of the head, but its just a spare for testing. the throat angle of the inlets seems pretty shallow.

as usual, comments, advice appreciated. if anyone on here has a lot of experience with flowing heads i'd love some opinions. must admit i'm not so interested in hearing about stuff that absolutely must be done to my engine but i cant be told about though!