I made some good progress with the M30 air box today. It looks like I should be able to use it after all! While the old-style 325e filter panel may be a bit larger, the design of the air box looks kind of restrictive, whereas the M30 box is very open. I measured the M42 and M30 air filter elements and here were my findings:

M42 filter: 68 pleats, 46mm x 137mm

M30 filter: 112 pleats, 46mm x 137mm

So, the M30 air filter has 65% more pleats / surface area. That should more than account for the ~53% increase in power that my new M42 will be making. Sweet. Enough talk though, let's see what the situation looks like under the hood!

This first shot shows the general positioning & fit of the M30 box under the hood. Easy, right? Well, I had to make some modifications to the PS reservoir bracket, charcoal canister position, the brake lines coming out of the ABS unit and the M30 air box itself. It isn't exactly plug & play lol (well, it sort of is now).

That intake boot sure looks close to the box right? Right. The top will be chopped and I am thinking about what will be the cleanest way to attach an adapter plate over the cut-out. The MAF needs a 6" or longer tube / velocity stack in front of it to work best. The easiest thing for me to do would be to cut the box, bend some 20ga mild steel sheet metal to cover the opening, and weld in some 70mm steel tubing...then the MAF can couple to that and it also serves as my velocity stack.

The line I marked on the box shows where the MAF ends when put into the boot, and its approximate angle.

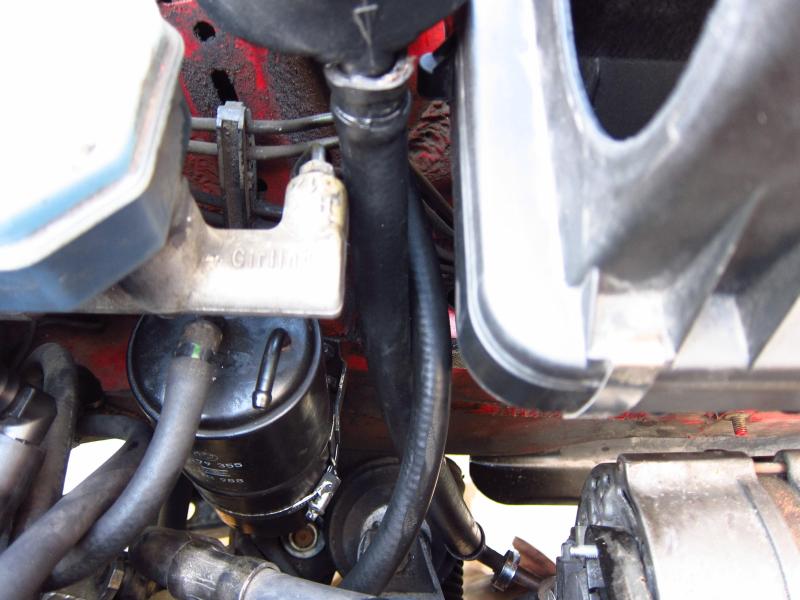

So, how tight IS the M30 box in there? Well, it just clears the PS reservoir. I can always push it up a little before tightening the band to buy more clearance, but the air box goes in & out fine as it is now.

The hoses have a decent amount of room now too. Just for reference, the reservoir bracket was modded to move things back 13mm and up about 25mm (more on this later). I hand-bent the brake lines a tiny bit here to keep them from contacting the PS lines, although it probably doesn't matter much.

LOTS of room up by the expansion tank. It seems like a lot compared to how it fit before I moved the PS reservoir & charcoal canister, anyway.

The rear stock rubber foot of the M30 box actually manages to sit nicely on the chassis. I do not like this though, and I will be machining a "socket" for the box so that it locks into the rubber cap thingy that the stock M42 air box uses.

The front rubber foot is just a few millimeters off of the sheet metal. No matter though, they are both going away!

Alternator clearance...check! servicing it is not an issue. The M30 box is actually the same width as the M42 box, and even a little less tall. It is just a LOT longer.

The fit around the ABS unit is very tight. I hand bent a couple of the brake lines to make sure that they weren't going to touch anything, and chopped off a couple of plastic ribs on the M30 air box that were interfering. The box now stays at least 5mm away from all parts of the ABS unit, and it will sit further once I make the box use that rubber mounting cap under it.

I needed to space the box out from the bracket to get the right clearance from the ABS unit. This was easily accomplished with washers. I may opt to bend the bracket though, to get an even cleaner stock look to this.

This is the area now that it is all cleared out. The black rubber thing in the middle is what I was talking about earlier. I'll get this box to sit nicely on / around it to keep it constrained while driving. As it is now, it can bounce up & down on its rubber feet, which is not tolerable.

So, what did I do to the PS reservoir bracket? First, it needed to move back toward the firewall about 13mm. That was fairly easy. I drilled a new bolt hole in the bracket 13mm from the original, and then cut off 13mm from the locking tongue at the bottom.

Next, I needed to move it UP. I drilled-out the spot welds holding the hoop to the mount. I then rotated the clasp so that it was not hitting the air box, and then I moved the hoop up on top of the bracket where I welded & ground it. I will probably clean & paint this to avoid rust.

Aaaah the MIG welder...the hot glue gun of steel!

Moving the charcoal canister was super easy. All I had to do was take the bracket off of the car, turn it upside down and reinstall everything. DONE!

Gee, it sure was convenient that I could just screw those rubber mounts into the air box! Well, not really. I had to drill some holes and put panel fasteners there (the M30 box comes with the nice one, on its other side).