Wiring:

I have been lead to believe that the H4 bulb cannot take both the current of the dip and main beam as it would just get too hot and bye bye bulb. So I'm going to use a 5 pin relay to switch between the two filaments.

What I'm going to do is use the dip beam 12v feed as the 12v feed for both the dip and main beam and switch between the two using the full beam circuit. So when the dip beam is switched, power goes to pin 87a to power the dip beam, when the full beam stalk is switched, it will send a current to pin 86 pulling the contact over to pin 87 (full beam side). This shouldn't be a problem with fuses as both lights use a 7.5amp fuse.

Then send the outputs to a water proof plug to allow seperation if I wanted to which then go to a plug on the bulb.

Diagram:

Note: DO NOT earth pin 87.

My new engine has now arrived really chuffed, means I can get on sorting out how it’ll all go together etc.

I bought my self a nice new engine stand to put it on, now I can start looking how the S/C and alternator will go on, get my newly balanced clutch and lightened fly wheel on and also my new pulley wheel.

I want to give it a good clean and maybe a splash of paint to smarten it up.

I invested in a new set of gaskets for the inlet and exhaust manifolds as well as new thermostat gaskets and seals, some bits were ok on the engine but I wanted the piece of mind that I had fitted new ones and nothing would be a problem.

Also, I have wanted to do an oil filter relocation set up. No major advantages just doesn’t look like any one else has done it (or got any pictures up) and thought it could be a nice addition to ye old engine bay. If I ever felt the need could always add a cooler too.

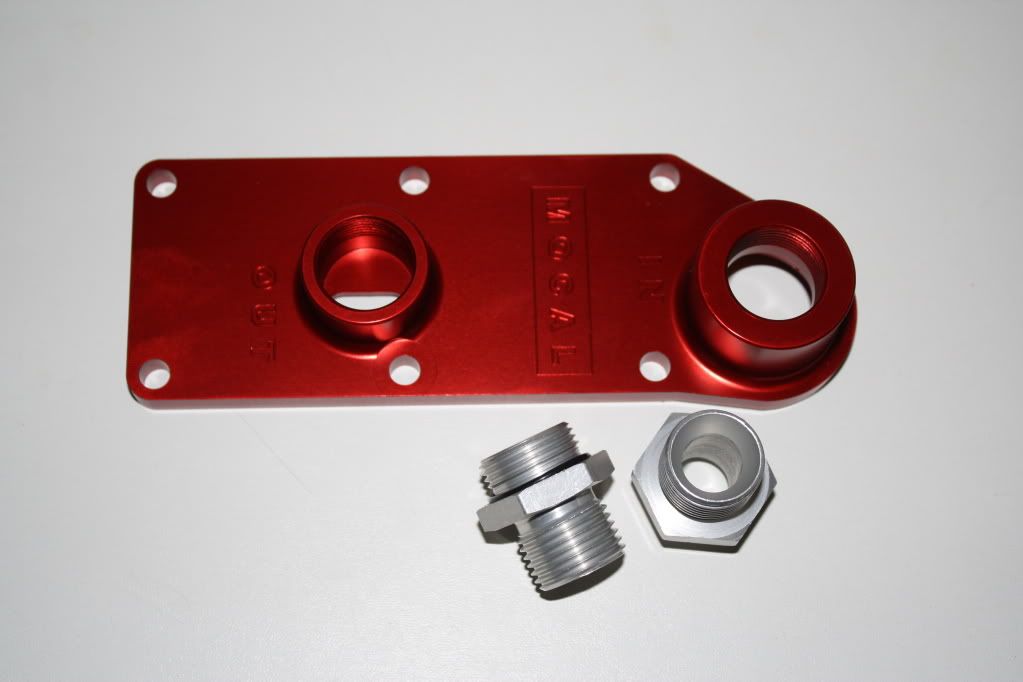

Got a good price on the take off plate to be bolted to block.

Got all my unions and bits today too:

Now for another of my wood, glue and metal, blue peter stylee mock ups winkeye I made a mock up of a remote head so I could find a position for it.

I was going to put it behind the N/S head light but thought there's already alot going on on that side so decided against it. I then remembered that I'm going to be moving the battery to the boot freeing up the space over there. There's space behind the engine to run the pipe work so its won first prize on going there, comme ca:

Big thanks to 'Think Automotive' who supplied me with the take off plate and also a custom remote head tapped to M12 x 1.5 thread for the OEM pressure switch.

UPDATE: Head arrived and got the pressure switch fitted:

Then placed it where it will eventualy live:

I also got a new front valance. Mine was bent where it must’ve hit a kerb previously and was a bit tatty so got a nice new one. Cut some material out so that the cooler hosing doesn’t rub and fail. Loads of room there now.

Got both my head lights in and wired up, whacked the grilles on to see how it looked