So, it looks like we are at the end of the overhaul (for now). This is probably the most images I have ever posted in a single thread lol.

The project is finally done! Six hours of wrenching this morning/afternoon got the last of it buttoned up, and it's on the road again.

What all did I do today? Well, I am glad that you asked (I know you did, don't lie). Well, I did a couple of things that I didn't take pictures of. For one, I removed the rear brake discs so that I could wipe off excess anti-seize from the parking brake shackles and pull the cable ferrules out to apply some to them. I also took the reinforced sway bar brackets off so that I could apply a little bit of silicone grease to the inside of the bushings. After that I put the exhaust back on the car and tightened the big bolt that secures the diff mount to the chassis (I used the jack to lift the diff up before tightening).

The topic of greasing stock rubber bushings seems to be one of those topics that nobody really has a solid answer for and it causes lots of debate. Overall, I am of the opinion that it is probably unnecessary unless specified by the factory. You want to be particularly careful not to use any pretroleum- or lithium-based lubes on the rubber bushings because it is going to shorten their life. Silicone lube is fine in most cases, and is what I used. So, why did I grease them? Well, remember that with any suspension bushing that involves a moving part through it, you absolutely do not want to tighten it down until the car is resting on the wheels with the suspension in its normal neutral position (don't just lower the car onto the wheels, roll it around a little so that the wheels settle). In this case, I didn't feel like dicking around under the car trying to tighten up stuff with it sitting down on the ground, so I lubed these bushings to allow the sway bars to move to the suspension's resting position without applying any undesired torque to the bushings. Recall that for the control arms and rear trailing arms, I did move the wheels to their normal position before tightening things up, and I did it without lube since those are much more critical.

Replacing the front sway bar bushings is a bit of a pain if you are using stock ones. I put a TINY amount of lube on the outside to allow them to slide into the shackles, and I put a little on the inside where they contact the bar as well. The rubber bushings need a lot of squeezing to get things into place! They have an orientation as well. Notice the chamfered side...this goes on the rearward side to clear the protruding portion of the subframe.

Getting the bar into place is super easy. You can unbolt one or both control arm lollipops to maneuver it into position.

Getting the shackle into place is a little bit of a chore. I have had great success (/Borat) using a floor jack (with pad removed) and vise grips. Just pay close attention to the tab that inserts into the subframe and make sure that it stays in. Once the jack has the shackle going into place a bit, use some vise grips to hold it in place. After that just install the nut & bolt! Make sure to check the shackle's tab to make sure that it looks fully engaged. Also don't push too hard with the jack because you don't want to bend the shackle.

The rest is pretty trivial. Install the linkage and call it done. In this case I opted to use Meyle HD drop links, and they can accommodate a 5mm allen key in the end which makes tightening the staked nut very easy. Others I have seen require you to jam a combo wrench up against the boot which sucks.

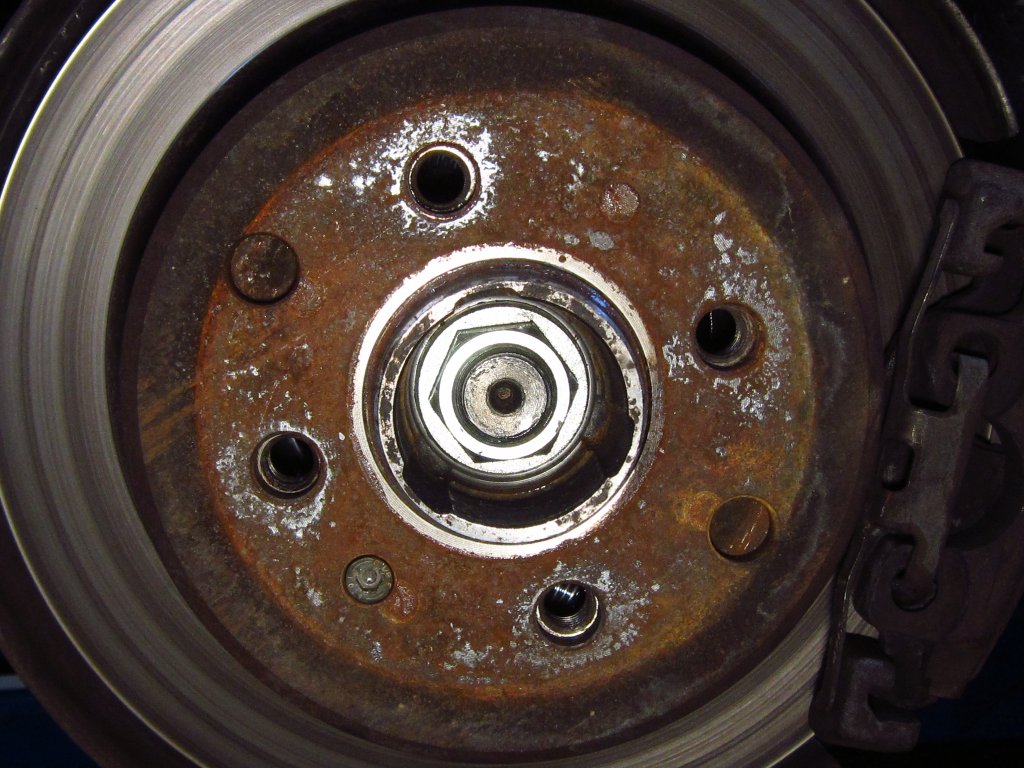

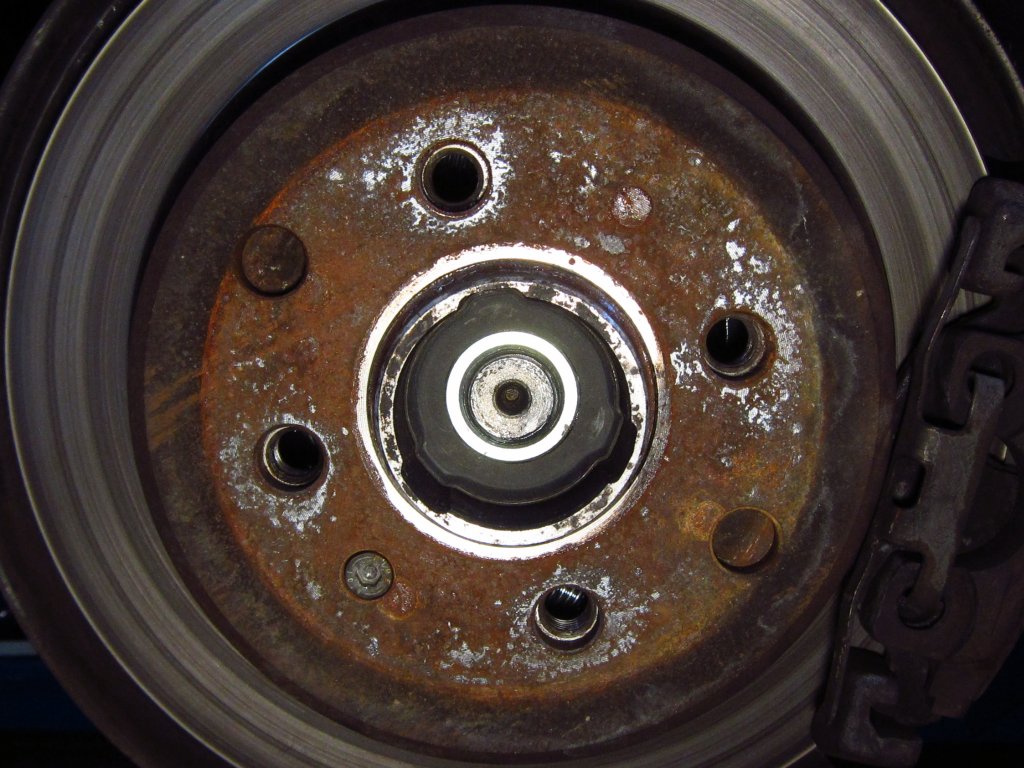

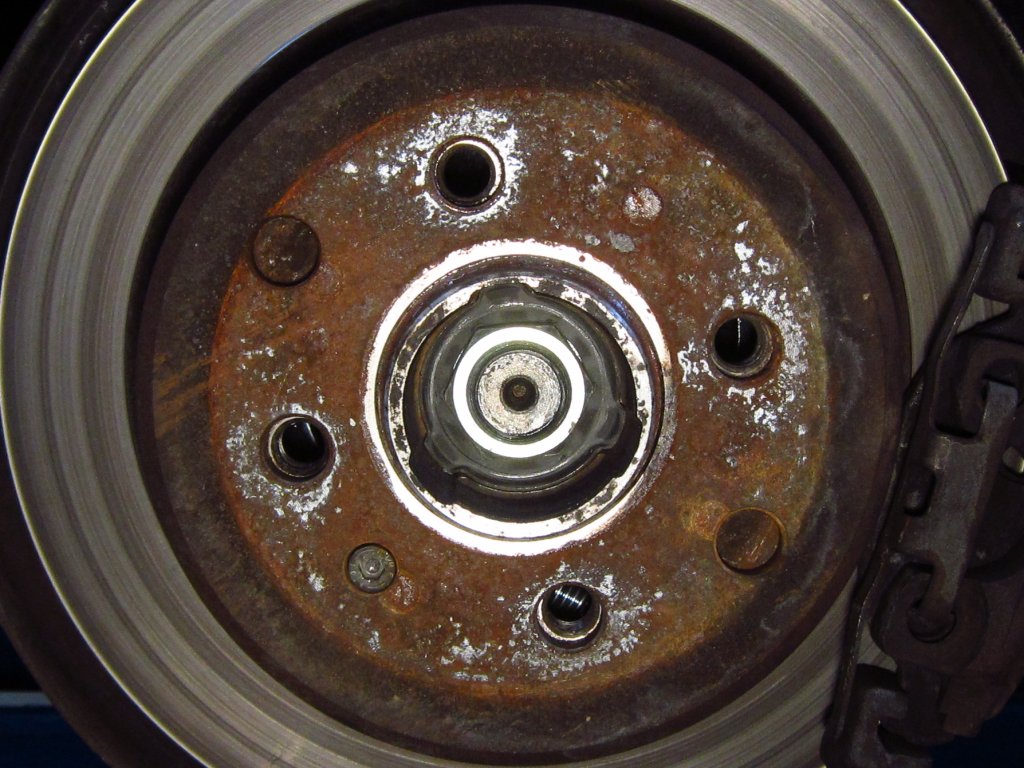

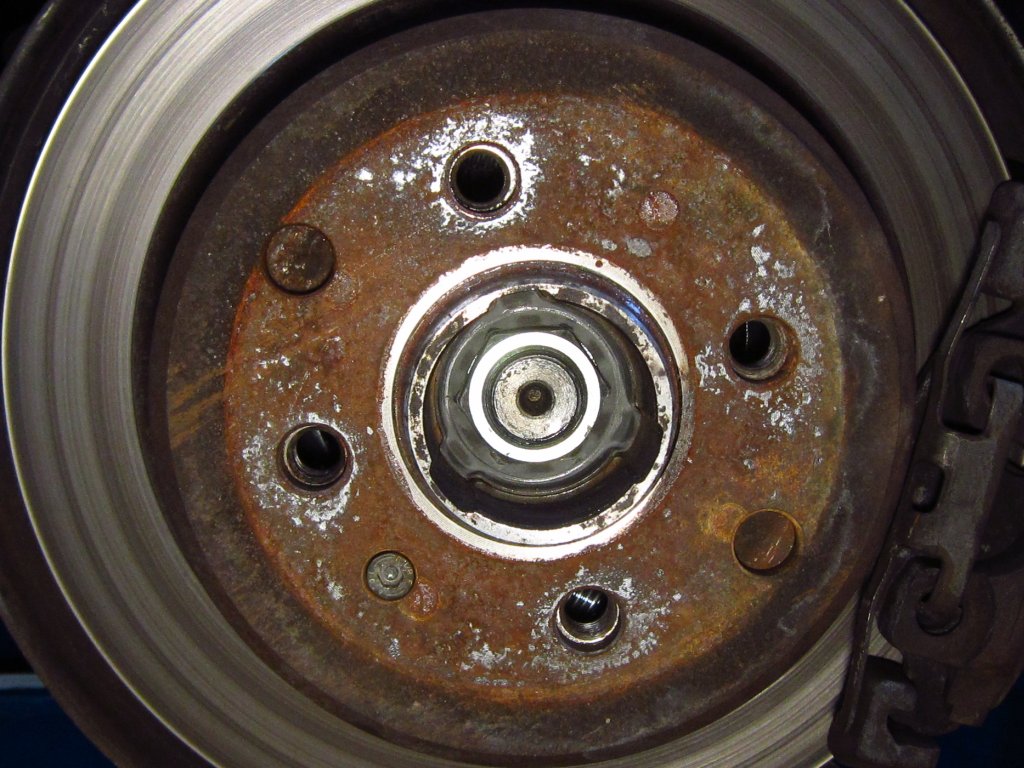

The other big items that I finished were the rear wheel bearings. I did these with the wheels off and the car up on stands so that no load would be placed on the bearings while the big 30mm axle nuts were tightened. Putting the car into gear and applying the parking brake was more than enough to hold things still while I applied the specified 145 ft-lbs of torque. Remember to apply some oil or grease to the flange n the back of the nut. This is called for in the factory procedure!

After that I installed the lock plates. You can do this with a rubber mallet, 1/2" extension, 32mm socket and 30mm socket. Do not use a metal hammer, despite the fact that it may seem easier.

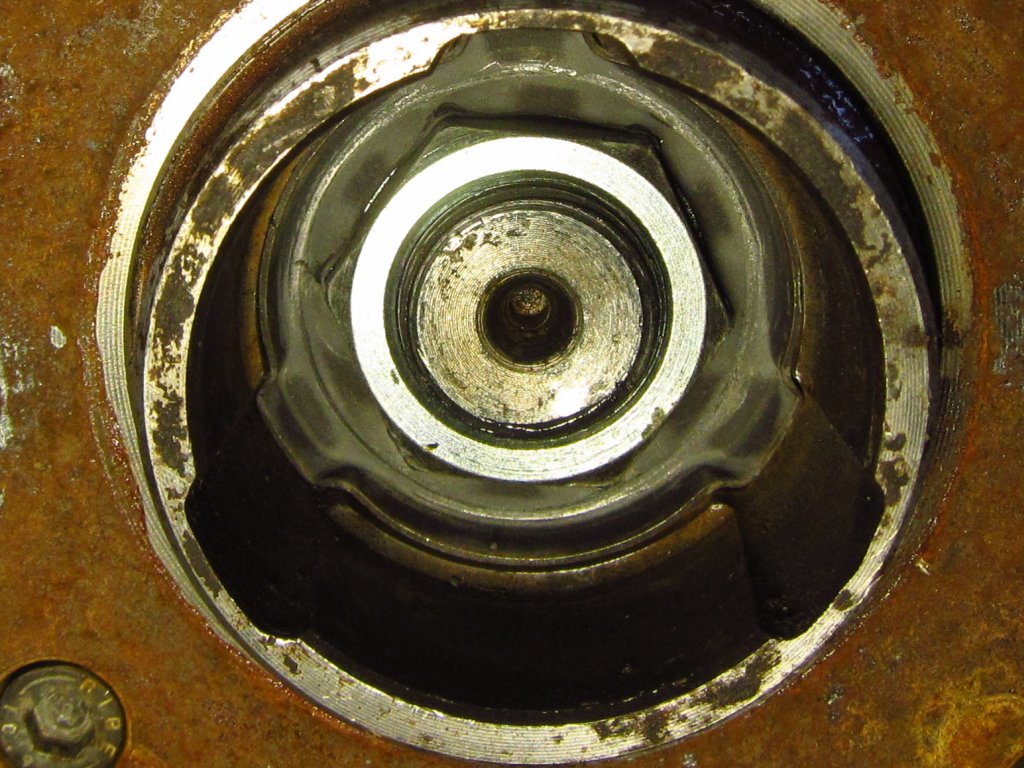

Slide the lock plate into the bore.

Use the 32mm socket and mallet to form the lock plate onto the nut.

Then use the 30mm socket and mallet to get the lock plate to bite down tightly onto the nut.

That's that. Other than that I just had to adjust the parking brake cables inside the car a little and bleed the brakes (did all four corners twice). Then it was test drive time. Overall, I LOVE it. The car rides a hell of a lot better and hugs corners much more tightly than before. Shredded subframe mounts were not helping anything before lol. I also really like the stock sway bars. The car feels a lot more balanced and less prone to understeer. Funny thing...it's almost as if BMW knew what they were doing when they designed these things!

Drivetrain noise is also greatly reduced. I have the iX VLSD in the car now, and while I don't plan to run it for very long, it is in a lot better shape than the small case LSD that was in there. It sounded like a coffee can full of rocks! The newly balanced driveshaft, new half shafts and all new wheel bearings probably also contribute to the smooth and quiet feel the car has now.

So I would say that this a big success overall, and it was well worth the hours of toil. Having owned an E30 with stiffer/lower shocks and springs, all poly bushings and mounts and beefy sway bars, I am going to say that an almost-completely stock suspension is best on the street. The car is pleasant to ride in both in terms of vibration and noise, it absorbs bumps easily and it handles fantastically. It just feels perfectly balanced and planted. While body roll has increased a little in my switch back to stock sway bars, it is made up for with what I think is improved grip (granted, some of that is probably because I have new subframe bushings and stuff). On a track, I would say that sure, go for stiffer bushings and a ride height drop because those things will pay off on nice perfect asphalt. On the street where the pavement typically sucks, however, I am a believer in a mostly-stock setup. The items that I think are worth upgrading / beefing-up are the shocks (Bilstein HD), the front CAB's (E36 M3 centered solid rubber) and the diff mount (E30 325iX solid rubber). I also have beefed up and reinforced rear shock mounts since the stock ones are known to be poop. Other than that though, the OEM bits are just fine.

I hope that people have found this thread useful and that maybe it will save people some time and effort. Everything is pretty straightforward with these maintenance items, it just requires some patience, careful thought about the order in which you do things, and more patience (and money...parts aren't getting any cheaper lol).