Alrighty party people, I think that I have found an issue, and probably THE issue. It seems like it should explain my very recent no-run / poor-running problem, as well as some intermittent wonky idle and infrequent low-load backfiring over the last year. Also, it is going to be expensive lol.

Things that need replacing:

- Crankshaft damper

- Accessory drive pulley

- Crankshaft position sensor

- Camshaft position sensor

- A crank position sensor bolt with mangled head

- Cam position o-ring

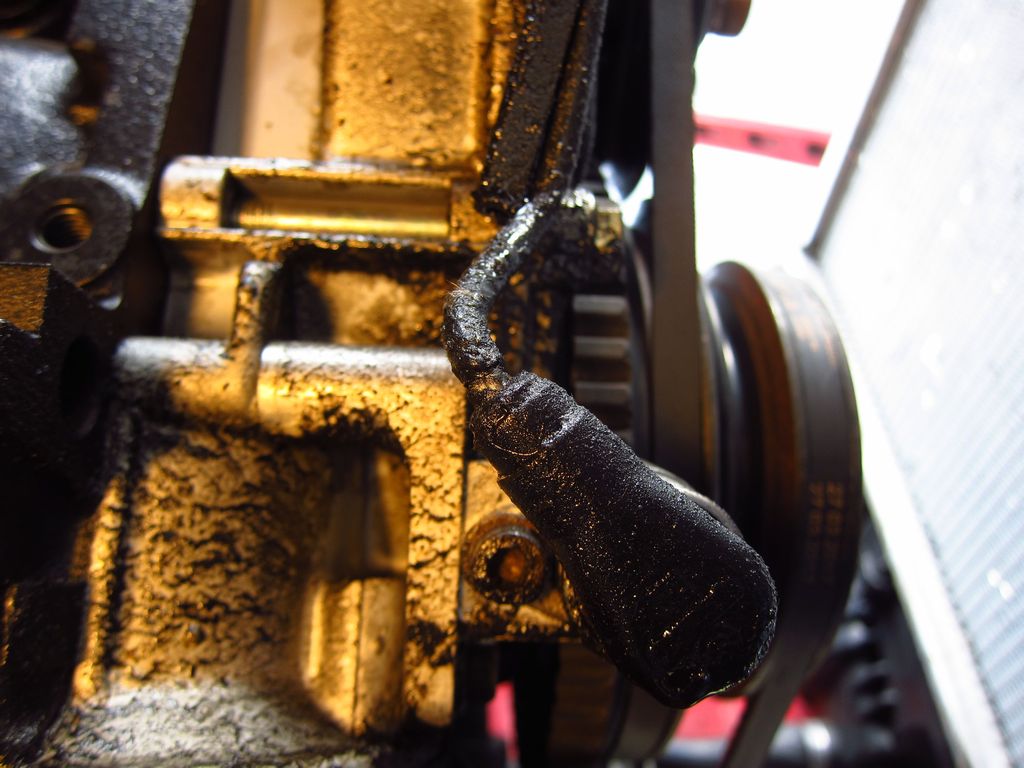

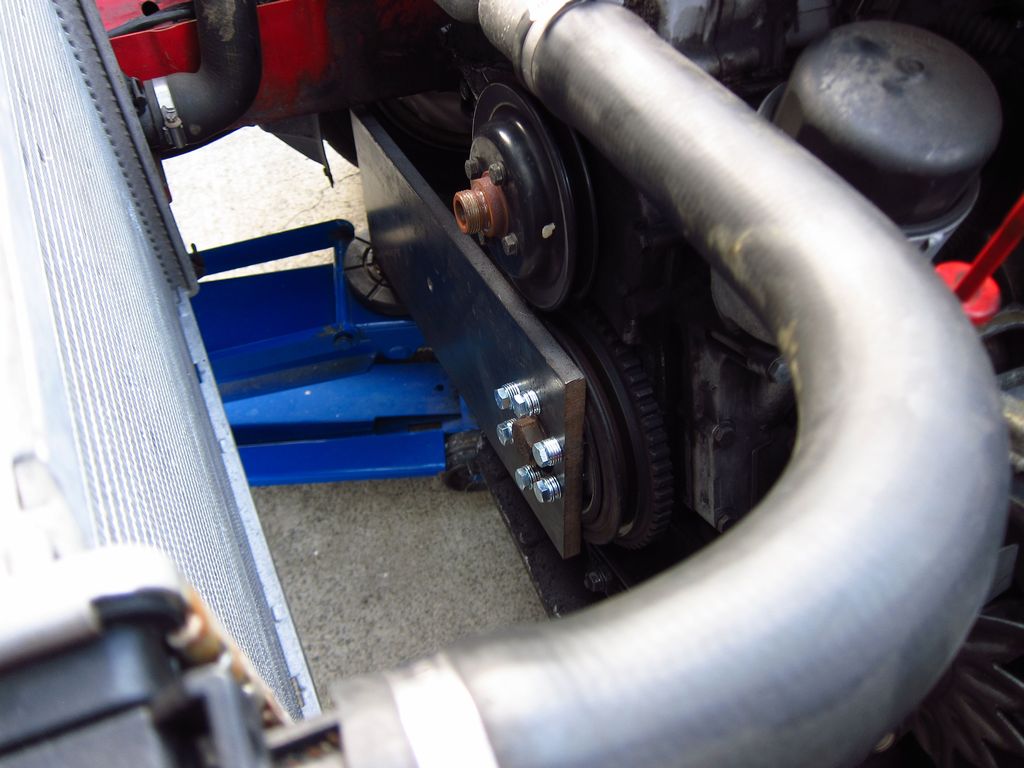

I pulled the belly pan and fan+shroud to get a good look at things today. Initially it looked like it was an obviously failing crank position sensor since the cable sheath was totally broken and the shielding was exposed.

The magnetic pickup head was a little dirty, but set at the correct distance from the teeth on the position wheel.

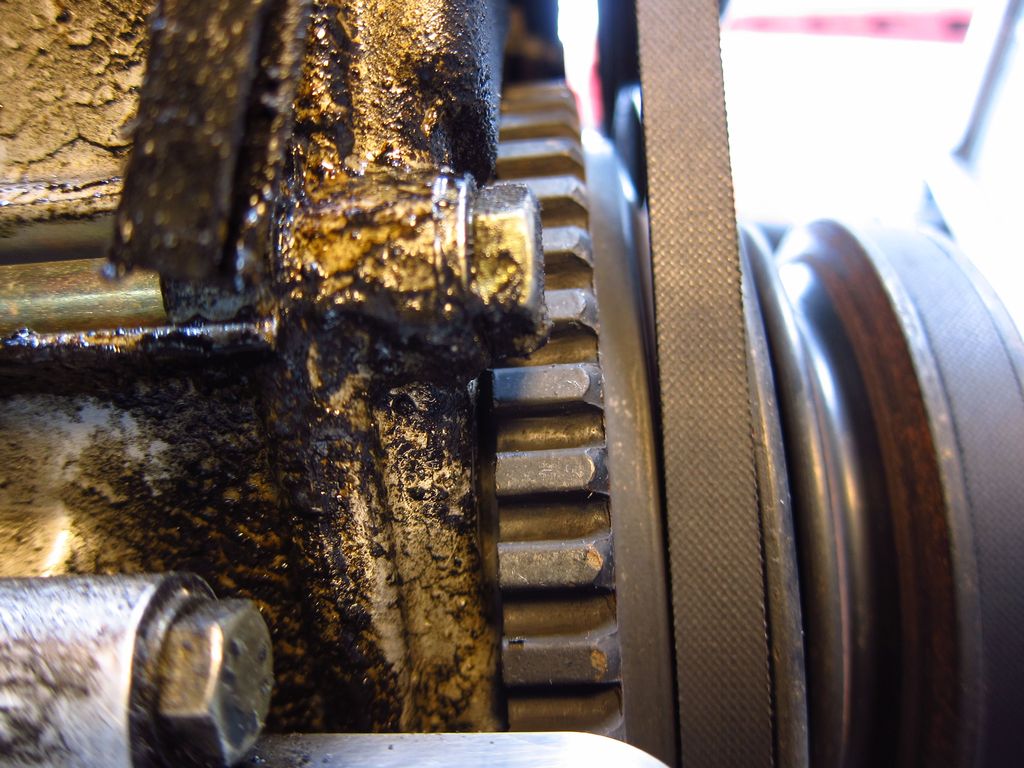

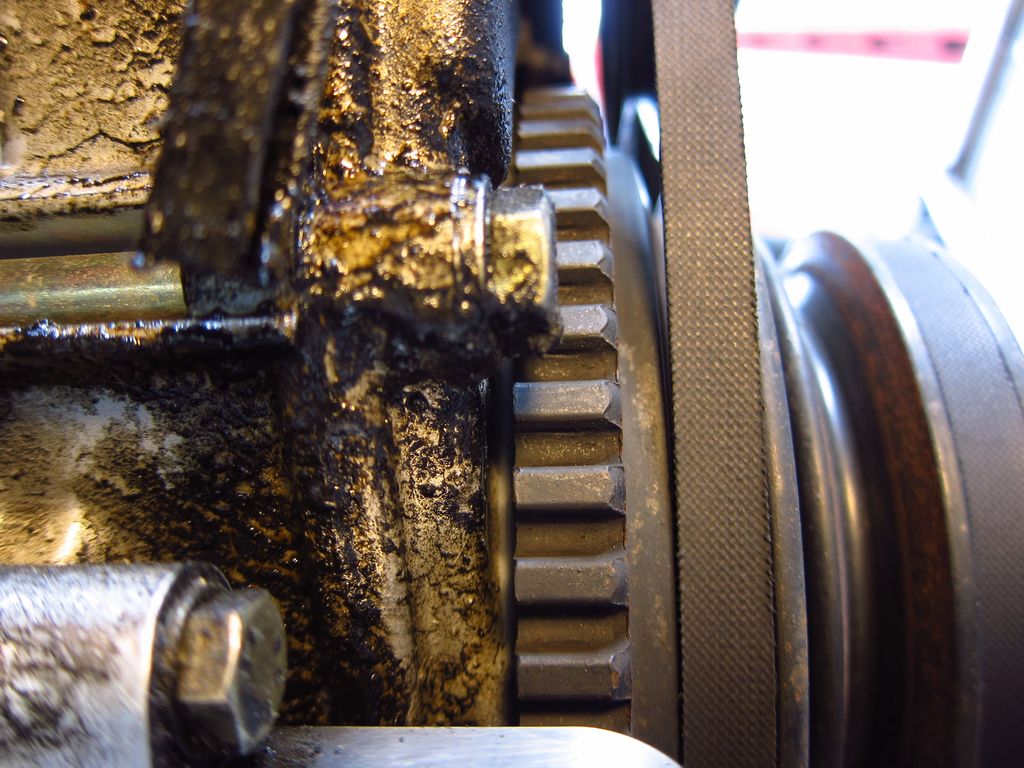

I then took a look at the damper wheel, and thought, "well I do not believe that there is supposed to be a big circumferential gap there."

Rotating the crank with a 27mm socket & ratchet, I noted that there was a lot of axial wobble, with the damper changing distance from the timing cover by a good ~3mm throughout its rotation.

There also appeared to be some evidence that the back of the teeth were making slight contact with the cover.

At this point, a number of things under the hood were clearly in need of removal, inspection and (in a week or so) replacement. I cleaned up the crank sensor and looked a little closer. While I do not think that any of the conductors were yet failed, it is only a matter of time until oil and other contamination get into the sensor body and finish it off. Additionally, the pickup face looks partially crushed, from god-only-knows what wrenching mishap in the last 13 years.

The cam position sensor's cable sheath was also failing in a couple of spots, so it is also being replaced. I did notice the super awesome micro TIG welds holding the pickup nub to the body. I thought that those were neat.

Next I wanted to remove the pulley drive hub to get a look around behind it. This time I was fully prepared, and no sweat was produced breaking the 250+ ft-lb bolt loose. 50" cheater-bar, custom crank locking plate & a floor jack to support the plate. No problem!

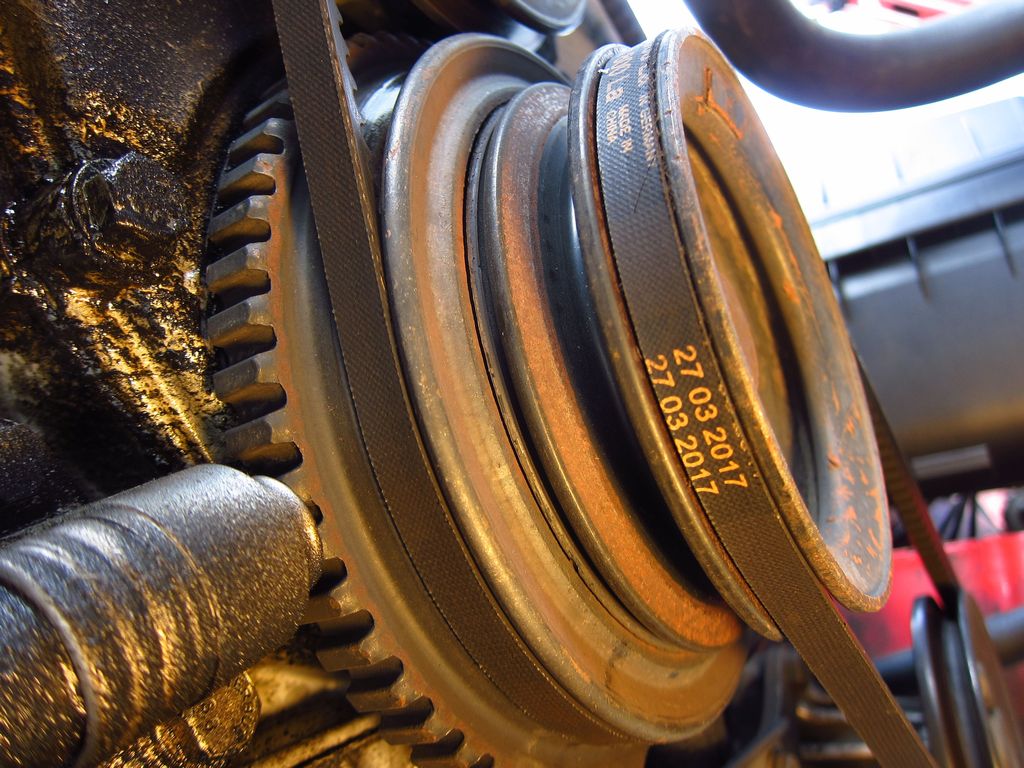

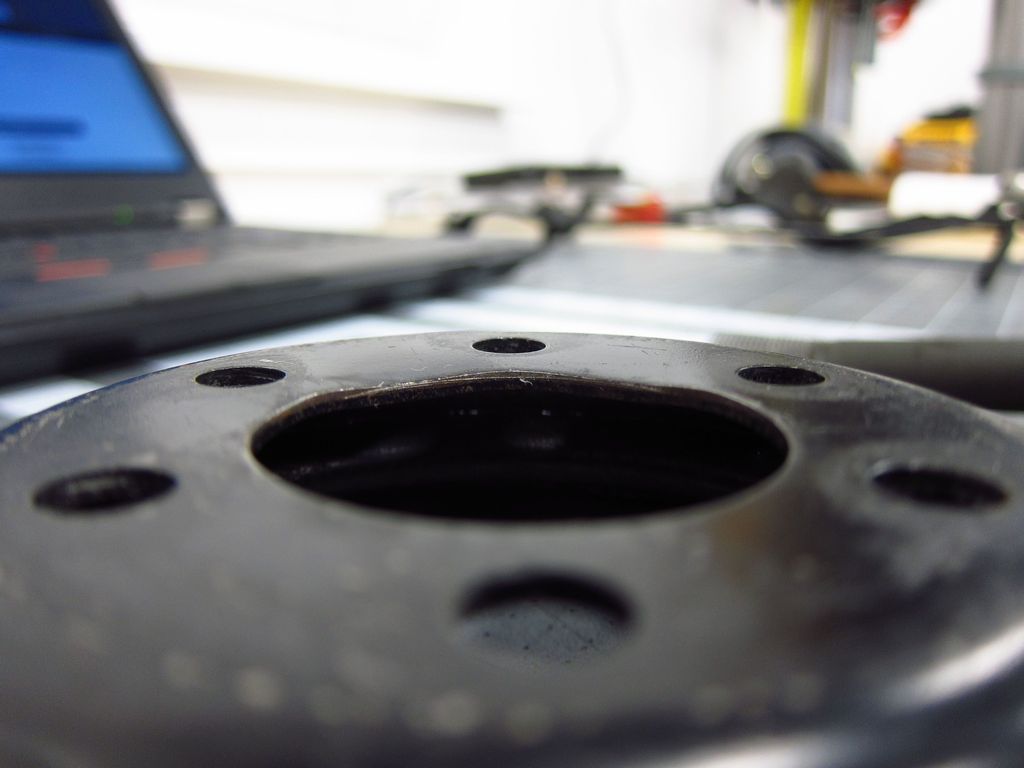

The position wheel + pulley was only ~40% attached to the driving hub. I could open it up pretty easily by hand, and a little more coaxing by my foot got it looking like this.

This thing is almost exactly 29 years old. It looks like it was produced in May of 1990.

A little more light pushing by hand completed the transformation into scrap.

I also noticed that the accessory drive pulley was a little bent up. Since the new damper wheel is ~$500, I am not going to bolt a bent thing to it (nor am I going to bother straightening it). It is getting replaced since it is simply not worth throwing the balance out or otherwise distorting the new damper drive hub.

Also, my engine uses a slightly different crank hub bolt than the stock E30 M42. Metric mechanic built it with this monster, and I will need to call them on Monday to get the proper torque spec for it.

You know you have been working on these things for way too long when taking the crank hub bolt off takes less than 3 minutes lol. Well, less than 3 if you don't count the trip to the hardware store for longer M8 bolts lol.

So there it is for now. I will be ordering the necessary parts to replace this old crusty crap, and hopefully the thing runs properly thereafter. Even if it is not the root cause, this stuff obviously needed replacing anyway.